Your Customers Deserve the Best

We are an SQF-certified co-packer with a thorough focus on quality control procedures. To ensure your contract beverage is the best it can possibly be, we conduct in-depth reports, rigorous inspections and analytical testing from the moment beverage blending is complete, to the time of canning. Some of our co-packing quality procedures include…

Automatic CIP and reports

We test meticulously in-line to ensure absolute consistency.

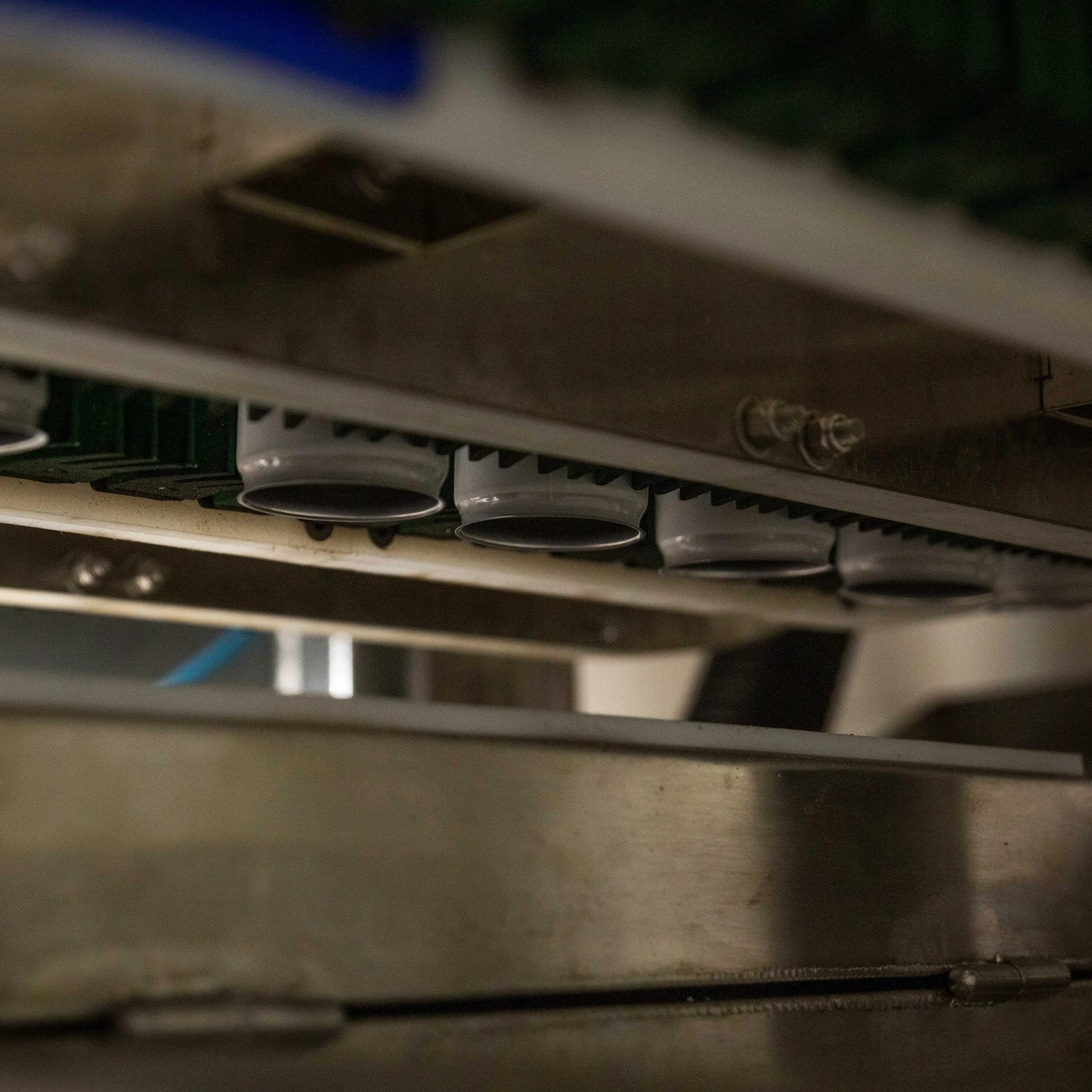

ionised air sanitisation

Each can is sanitised in-line using our ionised air system.

Seam inspection

Detailed Seam testing with our CMC-KUHNKE system.

ATP testing

We test frequently to ensure consistency of your beverage.

Fill Height Detection

Our X-Ray fill height detector ensures your beverage is always NMI compliant.

pH

testing

Our pH testing ensures you have the best quality water in your beverage.

Analytical Testing

We test Brix, pH, Density, ABV%, CO2 and dO2 to ensure each can is in spec.

Velcorin treatment

We use industry approved Velcorin to protect your beverage from contamination.