Pro Tech

With a variety of beverage production options to suit your every need, Pro Canning can assist in developing your solution for contract beverage production and co-packing. This includes Blending, Canning and Packing and Palletisation. We also have a variety of partners who specialise in all the Pre-Production steps to make sure you are 100% ready to dive into production.

200 Cans Per Minute

Canning speeds up to 200 cans per minute.

Advanced

Automation

Fully automated filling and packaging technology.

Any Size, Anytime

We offer every can size in the Australian market.

Laser Date Coding

In-line fully customisable batch and date coding.

Nitrogen dosing

Fast & reliable nitrogen dosing to the highest of standards.

BEVERAGE KEGGING

Package your beverage in Traditional or Key Kegs.

Ionised air cleaning

Ensure every can is perfect with ionised air cleaning.

BPA FREE CANS

We can connect you with the right supplier for BPA Free Cans.

Detailed Reporting

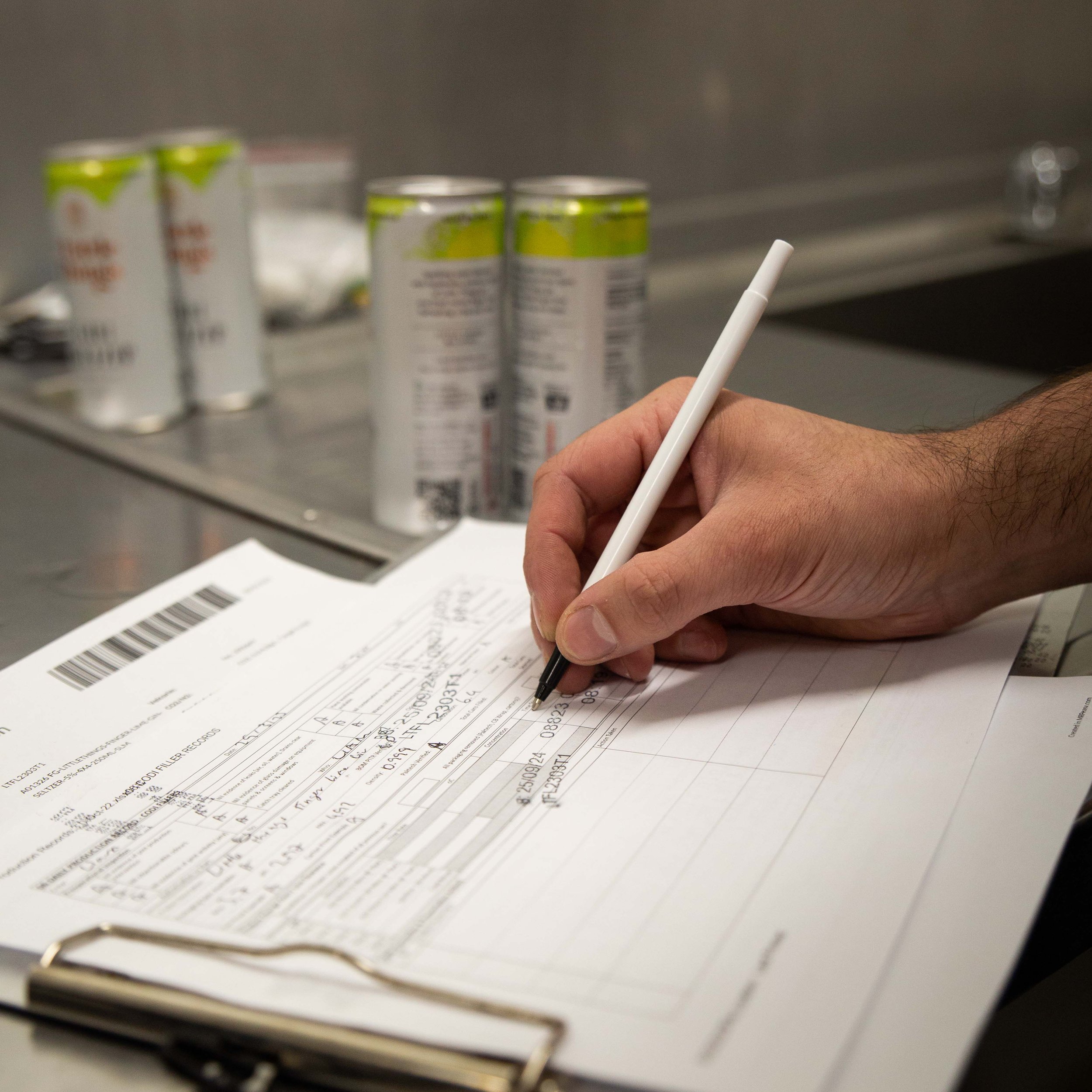

Comprehensive product and seaming reports.

Single-Can

Seaming

Be presentation ready with our single-can seaming solutions.